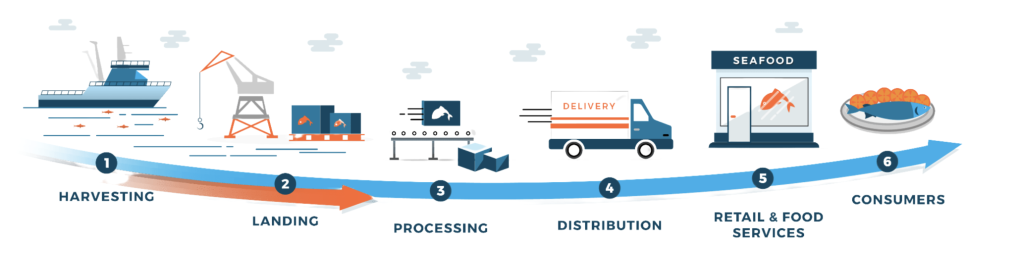

The global seafood industry, worth approximately $500 billion, faces a difficult traceability challenge given its long and complex supply chain.

ShoreKart is introducing a Traceability Platform(STR) with blockchain technology & IOT Sensors for fisheries data to trace the global seafood supply chain.

Discover who caught your Fish, Where it was caught and how

ShoreKart uses technology to trace its seafood products from the point of sale back to their point of origin, providing information on the fisheries and fishermen profiles are recorded at the vessel/dock, including information such as:

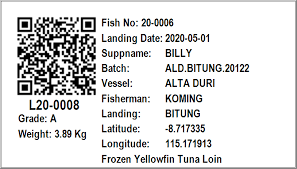

At receiving, each fish is graded and tagged with human-readable data.

Each fish is individually issued for processing to fulfill specific orders. The inventory tag is scanned and the issuance tag is generated with cut specifications

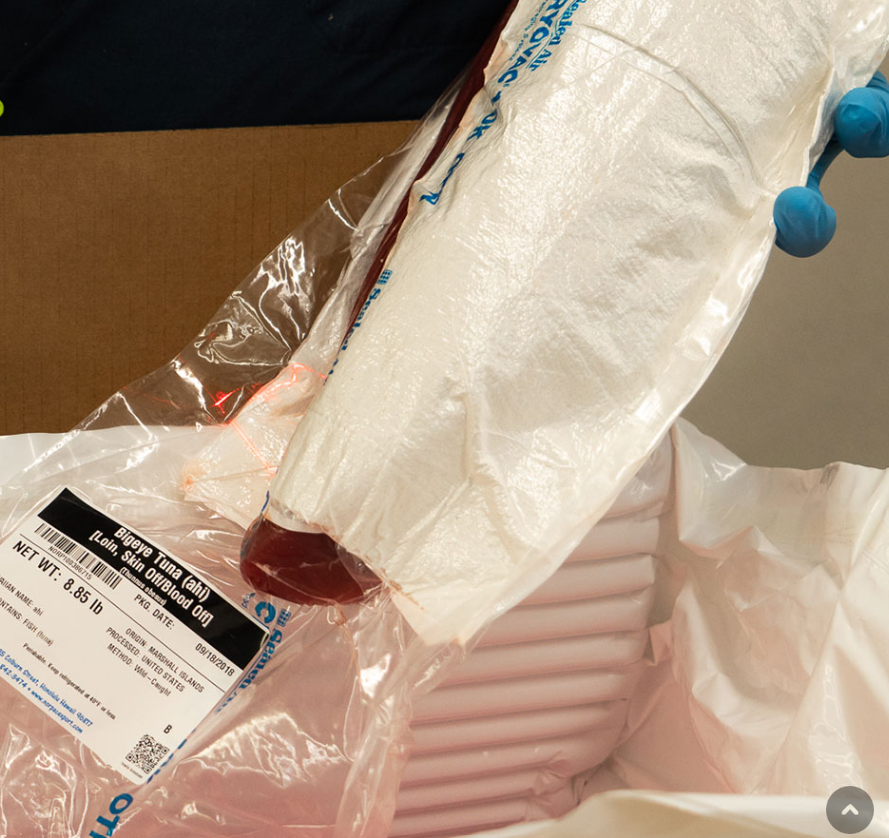

After issuance and processing, each piece is weighed, barcoded, and grade is examined for quality control.

Each cut is individually scanned to the specific customer work order.

Telling stories about

fishermen or farmers on the product packaging allows for increased prices and promotes brand loyalty with

consumers. For example, small-scale fishing organizations that have implemented consumer-facing traceability systems have seen increases of 18%–30% in margins.